PEAK FIRES UP FUSION

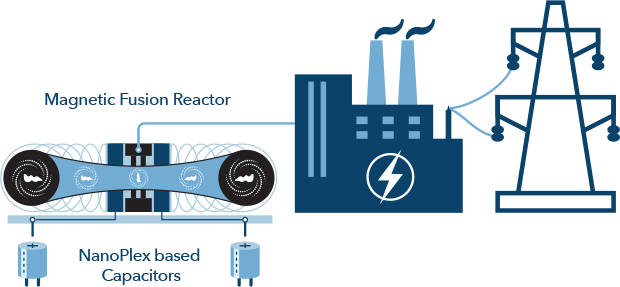

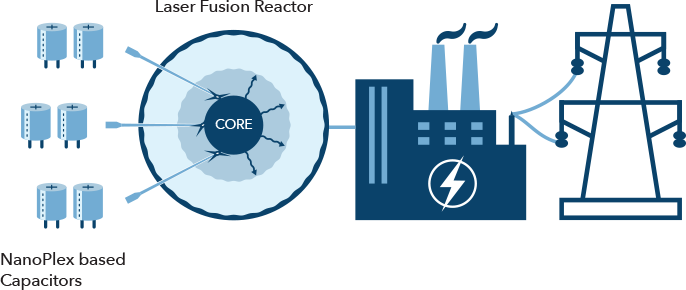

NANOPLEX-BASED CAPACITORS FIRE FUSION REACTORS

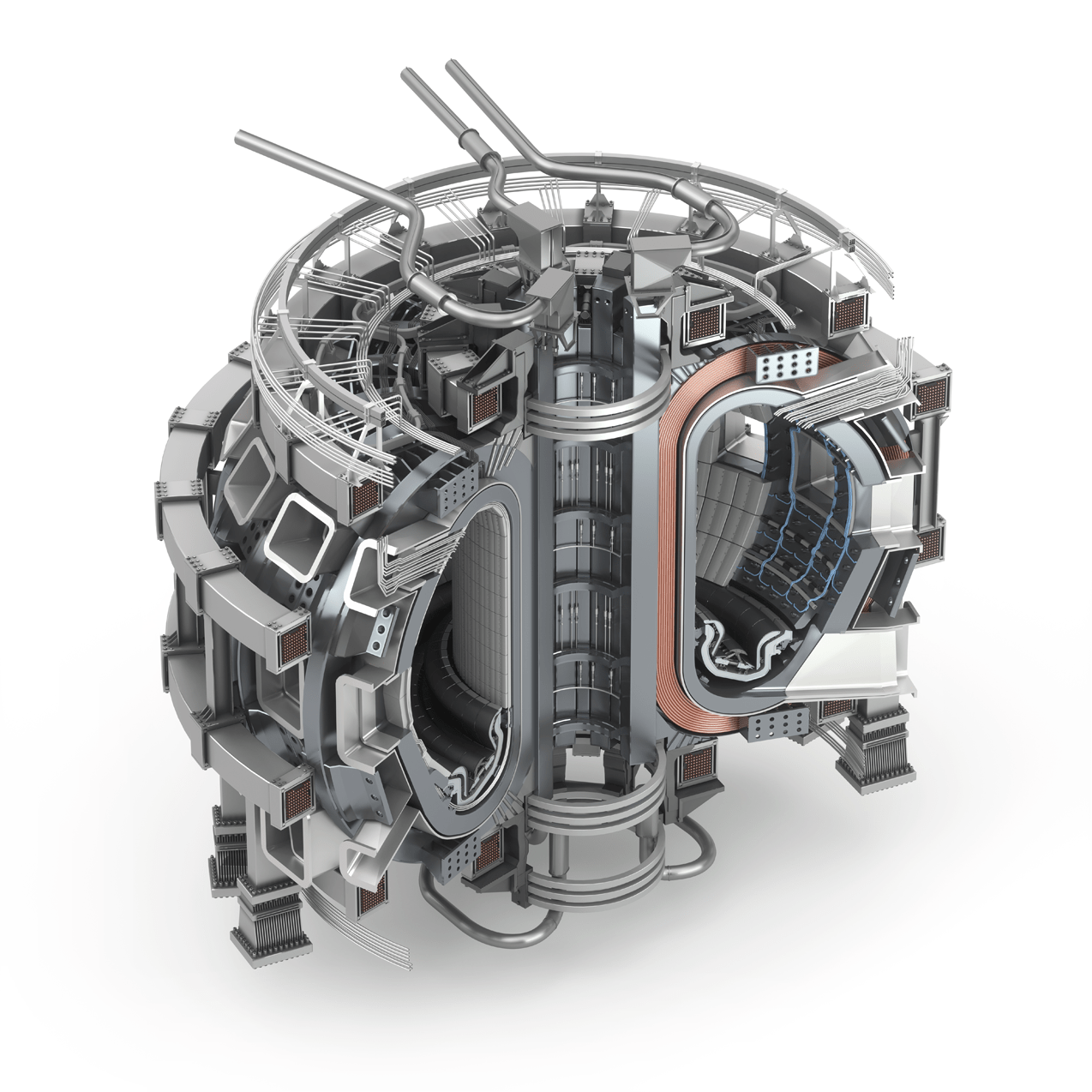

Fusion energy powers our sun and all the stars in the universe and has the potential to provide nearly unlimited amounts of clean energy. The process is theoretically simple. Hydrogen atoms can be superheated, fusing together, producing helium and clean energy. The implementation is a bit more complicated and requires hundreds of high-powered lasers or magnets to recreate the fusion process in a controlled manner. Self-sustainable fusion requires reactors that can operate on a 24/7 basis to provide the energy our world needs to replace fossil fuel and nuclear fusion power plants.

Peak’s NanoPlex films are being incorporated into next-generation high-performance capacitors to provide the massive bursts of power required to power those lasers and magnets,

increasing fusion effectiveness, efficiency, operational lifecycles, and production readiness.

PULSED LASER INERTIAL CONFINEMENT

-

Improving Fusion Power Generation

NanoPlex-based capacitors will enable fusion power plants to improve their power generation efficiency ratio (power required to generate fusion vs. the power multiple produced for consumption), which lowers the cost per kilojoule.

-

Stronger Power Bursts

NanoPlex-based capacitors can store up to 2-4x more power than industry standard Biaxially Oriented Polypropylene (BOPP) capacitors, enabling fusion reactors to be more efficient.

-

Lower Operational Cost

NanoPlex-based capacitors will lower the cost of operating and maintaining fusion power plants, increasing power generation, improving uptime, and reducing the power plant’s footprint to house pulsed power capacitors.

MAGNETIC FUSION REACTOR

-

Improving Fusion Power Generation

NanoPlex-based capacitors will enable fusion power plants to improve their power generation efficiency ratio (power required to generate fusion vs. the power multiple produced for consumption), which drives/lowers the cost per kilojoule.

-

Up to 5X Longer Duty Cycle

Based on improved temperature ratings, NanoPlex LDF-based capacitors will have up to 5x longer lifetimes than BOPP capacitors.

-

Lower Operational Cost

NanoPlex LDF-based capacitors will lower the cost of operating and maintaining fusion power plants, increasing power generation, improving uptime, and reducing the power plant’s footprint to house pulsed power capacitors.