Nanoplex Metamaterials

What is a Metamaterial?

Metamaterials are engineered materials designed to have properties not found in naturally occurring substances. They are created by arranging materials in specific configurations at a nanoscale, often smaller than the wavelengths of light, sound, or electromagnetic waves, which enable them to create new ways to manage our world and shrink the size of materials used in products.

Peak is a leader in nanolayered metamaterials. Our patented NanoPlex solutions are engineered and manufactured in the United States. NanoPlex enables researchers and engineers to reimagine how we solve some of the world’s biggest problems. Our films can be designed and manufactured with over 4,000 layers, pushing material science to new heights and allowing us to create truly novel solutions with our researchers, engineers, and partners.

THE PROPERTIES OF METAMATERIALS

The Magic of Metamaterials

Metamaterials are artificially engineered materials

designed to have properties not found in naturally

occurring substances.

NanoPlex - 4k

Nanoscale Layers

NanoPlex is a family of nanoscale metamaterials that can be programmed to enhance performance in a variety of applications including optics, energy storage, product packaging, and protective films, to name just a few.

Revolutionary

Rheology

Peak has advanced the science of rheology, a branch of physics that deals with the deformation and flow of matter, especially the non-Newtonian flow of liquids and the plastic flow of solids.

Up to 4x More

Energy Storage

NanoPlex has revolutionary energy storage capabilities that enable our high dielectric constant capacitor films to handle high energy charge and discharge in pulse power applications such as jet propulsion systems and fusion energy.

up to 3-5x Longer

Power Operations

NanoPlex has been engineered with exceptional thermal properties, enabling our low dissipation factor capacitor films to operate up to 3-5 times longer than standard biaxially oriented polypropylene.

Protective Films

Peak’s film technology can be adapted to support several uses for aerospace, medical packaging, and food storage to protect these items from excess light, radio waves, and atmospheric conditions.

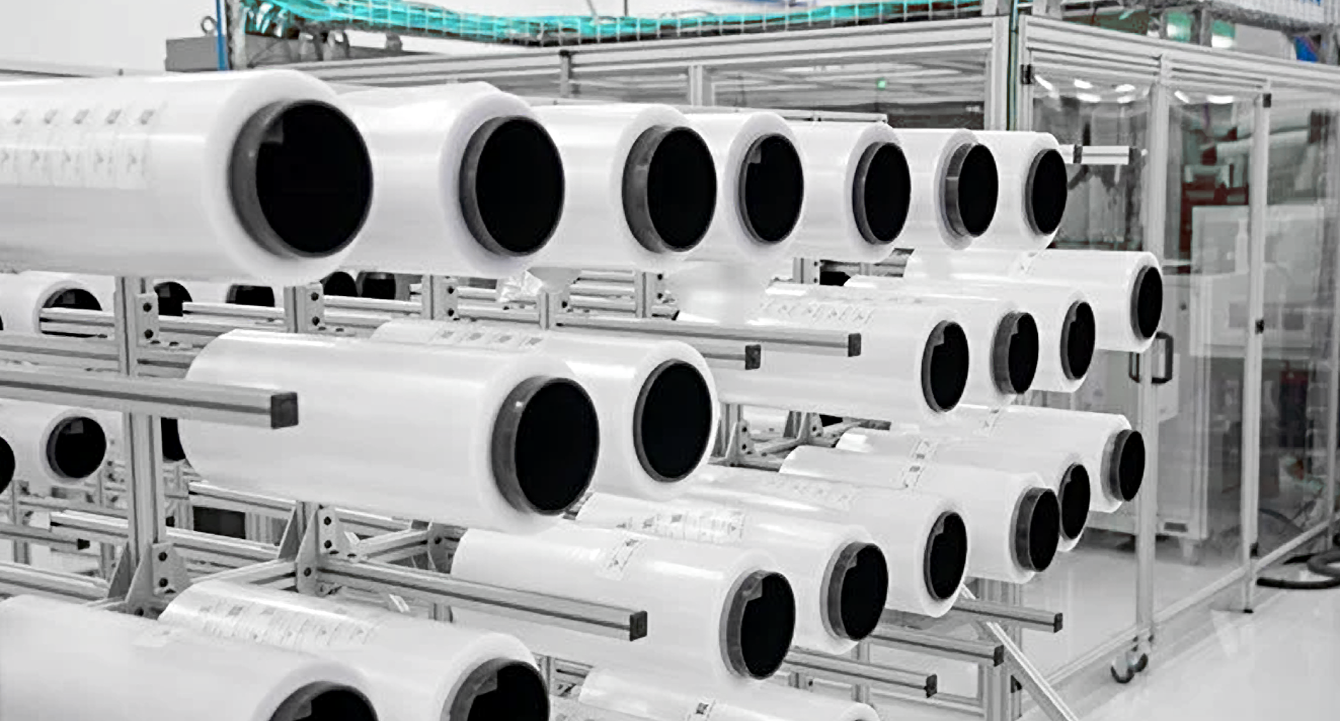

NanoPlex Metamaterial Manufacturing Science

NanoPlex films require not only new product science but also new manufacturing science. Peak has created new methodologies for the development of metamaterials, including the ability to control material layers at nanometer thicknesses while maintaining the integrity of each layer across thousands of layers.