Peak NanoPlex™ Low Dissipation Factor Film (LDF)

High-Temperature Capacitor Films for High-Performance Capacitors

Request a Sample KitLow-Loss Capacitor Film Delivering Stable Dielectric Performance

NanoPlex LDF is a capacitor film designed to outperform conventional BOPP. With a low dissipation factor and stable dielectric behavior up to 135°C, it’s engineered for high-frequency, high-temperature applications like fusion energy systems, EVs, renewables, HVDC, grid, and pulsed-power defense platforms.

Easily metallized and wound using existing infrastructure, LDF eliminates the need for major retooling. By extending operational lifetime and thermal reliability, it slashes maintenance costs and enables more compact, efficient system designs.

Next Generation Low Dissipation Film

Rated Up to 135 Degrees Celsius

Performs at higher operating temperatures with no derating.

Low Dissipation Factor (DF = 0.00025)

Higher thermal thresholds (DF maintained <0.0004 to 150°C)

Built for Harsh Duty

Handles thermal and mechanical stress with <1% shrinkage at 130°C.

Drop-In Ready

Metallizable and windable using standard processes.

Up To 5x Longer Lifespan

Longer Capacitor lifecycles, less maintenance cost

U.S.-Engineered, Lab-Tested

Backed by ASTM and JIS-certified performance data.

What Is Peak NanoPlex™ LDF

Peak NanoPlex™ LDF vs. Traditional Capacitor Films

| Feature | Traditional Capacitor Film (BOPP) | Peak Nano LDF Film |

|---|---|---|

| High-Temperature Performance | Performance declines above 85°C | Rated for 135°C operation without derating |

| Dissipation Factor | Higher losses under similar conditions | Ultra-low: 0.028% at 25°C, 1kHz (ASTM D150) |

| Breakdown Strength | Typically 800 V/µm | 700 V/µm (ASTM D149) |

| Shrinkage Stability | Susceptible to dimensional drift above 100°C | Minimal: <1% at 130°C (JIS K7133) |

| Mechanical Strength | Lower strength in high-heat cycling | 63 MPa (MD) / 33 MPa (TD) (ASTM D638) |

| Thermal Fatigue Resistance | Prone to failure and performance loss over time | Maintains energy delivery under repeated high-duty pulse loads |

| Film Handling | Industry standard | Designed to metallize and wind like BOPP |

| Service Life | Shorter life, especially at high frequency or temperature | 5x Longer life under thermal and electrical stress |

| Supply Chain | ~70% of global supply comes from China | 100% U.S.-based production with allied-sourced materials |

| Commercial Readiness | Mature, but aging technology with performance limits |

Sample availability in 2025–2026, with production scale-up planned for 2027 |

Applications

Electric Vehicles

Power Grids

Magnetic Fusion Systems

Ready to Evaluate NanoPlex Films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

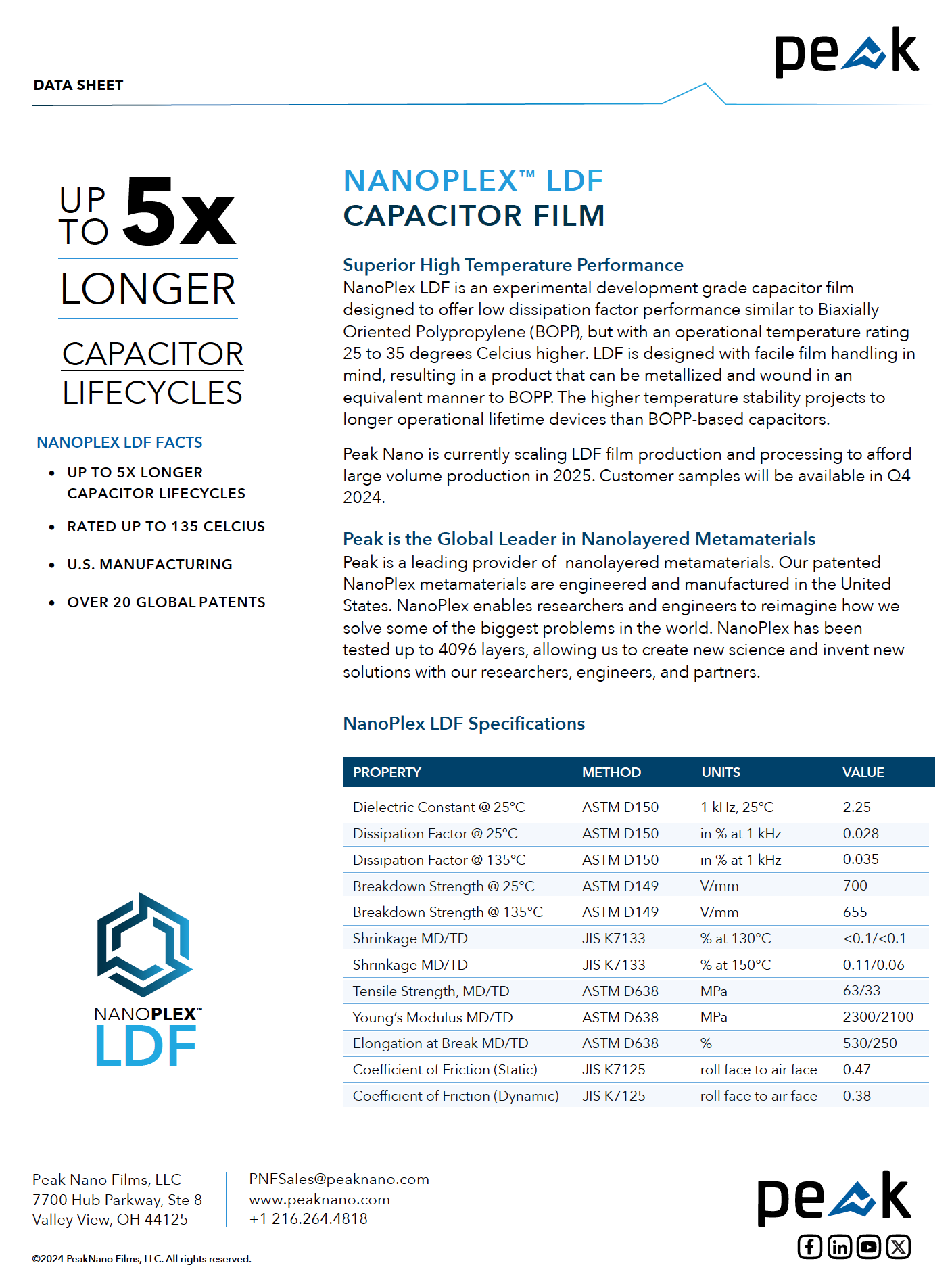

NanoPlex™ LDF 1400 Specifications

| Property | Method | Units | LDF 1400 |

|---|---|---|---|

| Dielectric Constant @ 25ºC | ASTM D150 | 1 kHz, 25ºC | 2.25 |

| Dissipation Factor @ 25ºC | ASTM D150 | in % at 1 kHz | 0.02 |

| Dissipation Factor @ 135ºC | ASTM D150 | in % at 1 kHz | 0.035 |

| Breakdown Strength @ 25°C | ASTM D149 | V/µm | 700 |

| Breakdown Strength @ 135°C | ASTM D149 | V/µm | 655 |

| Shrinkage MD/TD | JIS K7133 | % at 130°C | 2.1/0.24 |

| Shrinkage MD/TD | JIS K7133 | % at 150°C | 2.8/0.44 |

| Tensile Strength, MD/TD | ASTM D638 | MPa | 63/33 |

| Young’s Modulus MD/TD | ASTM D638 | MPa | 2300/2100 |

| Elongation at Break MD/TD | ASTM D638 | % | 530/250 |

| Coefficient of Friction (Static) | JIS K7125 | roll face to air face | 0.47 |

| Coefficient of Friction (Dynamic) | JIS K7125 | roll face to air face | 0.38 |

Frequently Asked Questions: NanoPlex™ LDF Film

NanoPlex LDF offers a higher operational temperature range - up to 135°C - compared to BOPP’s ~85°C limit. It delivers a similar low dissipation factor (extended to 150°C) while enabling longer device lifetimes, smaller form factors, and more reliable high-temperature performance.

Yes. LDF is engineered for compatibility with existing BOPP processing tools. It handles like standard BOPP film, minimizing retooling or requalification requirements for capacitor manufacturers.

Higher thermal stability means capacitors can operate without derating in elevated temperature environments. This results in fewer components, reduced cooling needs, and longer operational life. This is critical for fusion energy, defense systems, and grid modernization.

Samples are now available throughout 2025–2026, with large-volume production planned for 2027 at Peak Nano’s U.S.-based manufacturing facility.

More than 70% of BOPP film is sourced from overseas, often with uncertain lead times and geopolitical risk. Peak Nano’s U.S.-based production provides a secure, compliant, and resilient supply chain for critical industries.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.