Mobile Power Distribution

Peak NanoPlex™ capacitor films deliver more energy in less space, last longer, and keep voltage stable in mobile environments.

Transform Mobile Power with NanoPlex™ Capacitor Films

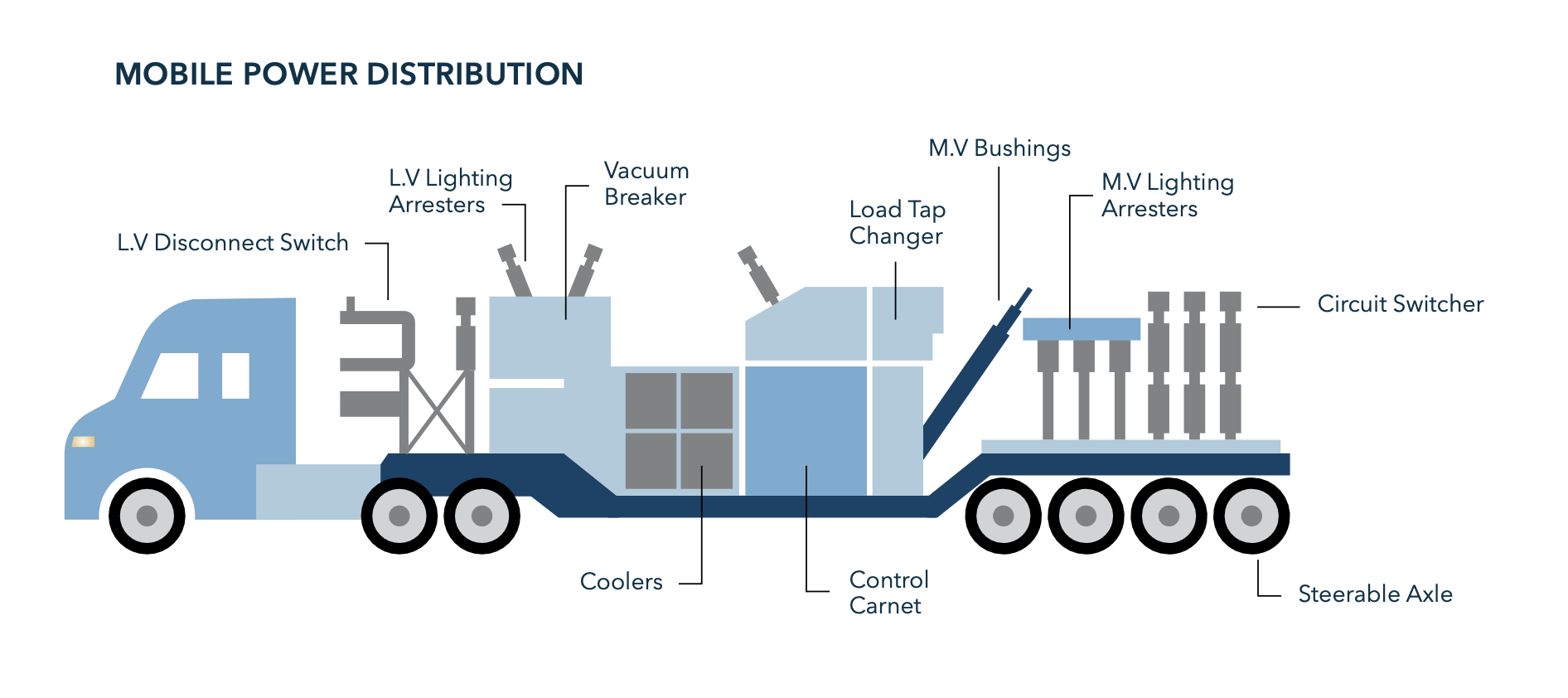

Mobile substations for utilities, defense, and disaster response need lighter, tougher, longer-lasting components.

- NanoPlex HDC capacitor films provide 4x more energy stored in the same footprint.

- NanoPlex LDF capacitor films deliver reliable high-current performance, last up to 5× longer, and provide a drop-in upgrade that reduces maintenance and downtime in mobile power solutions.

Lighter Capacitor Solutions for Mobile Power Distribution

- Traditional capacitors weigh more and store less energy, wasting space and limiting mobility in the very moments when speed matters most.

- Peak NanoPlex HDC capacitor films change that, storing up to 4x more energy in the same volume, so systems can be 50% smaller and 30% lighter.

- Crews can respond faster with fewer people and less equipment, restoring power quickly in disaster zones, remote sites, and demanding environments.

- The result: Mobile units that are easier to move, quicker to install, and ready to deliver power when and where it’s needed.

Dependable Power in Harsh Conditions

- Traditional capacitors wear out quickly under heat and heavy use, leading to repeated failures, constant replacements, and higher maintenance costs. For mobile power units, that means more downtime and less reliable power when it’s needed most.

- Peak NanoPlex LDF films last up to 5x longer, remaining dependable even in extreme temperatures and demanding conditions, while cutting maintenance cycles and reducing service costs.

- Keep systems online longer and maximize uptime in the field, allowing field operators to deliver power consistently.

Reliable Power Without Heat Limits

- In hot environments, mobile power units can lose performance. Traditional capacitors start to fail above 85°C, forcing engineers to oversize systems or add costly cooling. The result is heavier, more complex equipment that’s harder to deploy and less dependable in the field.

- Peak NanoPlex LDF films solve this challenge by running reliably up to 135°C with no derating or performance loss. That means smaller, lighter systems that cut costs.

- Maintain full power in sealed enclosures, compact designs, or scorching outdoor conditions with reliability.

Achieve Reliable Performance in the Toughest Mobile Applications

- Mobile power systems work best when every piece of equipment gets steady voltage. Traditional setups with shifting loads often struggle, resulting in fluctuations that compromise efficiency and strain sensitive equipment.

- Peak NanoPlex LDF films keep power stable, even under heavy switching and changing demand by delivering cleaner voltage and reducing system stress; they improve efficiency and protect critical equipment under strenuous environments.

Lower Costs and Extend the Lifetime of Mobile Power Units

- Traditional film capacitors run hot, wear out quickly, and force engineers to design larger, heavier systems with added cooling. The result is higher equipment costs, more frequent replacements, and more fuel and logistics expenses in the field.

- Peak NanoPlex LDF films reduce cooling requirements and last 5x longer, resulting in less maintenance, fewer replacements, and lower downtime costs.

- Operators can reduce both upfront spending and long-term operating expenses.

U.S.-Manufacturing Provides Critical Component Access by Cutting Supply Delays

- Relying on imported capacitor films means longer wait times, unpredictable costs, and vulnerability to global disruptions. For utilities and OEMs, this risk can delay projects and compromise reliability where power is most needed.

- Peak NanoPlex capacitor films change that with a fully U.S.-engineered and domestically manufactured supply, built with materials sourced only from allied nations. This stable, secure supply chain ensures dependable access to critical components, reducing risk for helping utilities and operators.

Traditional vs. Peak NanoPlex™ Capacitors for Mobile Power

With NanoPlex, mobile substations and hybrid PFC banks become lighter, cooler, and more reliable, delivering stable voltage, reduced fuel and maintenance costs, and a secure U.S.-based supply chain for critical missions and grid resilience.

| Category | Traditional Capacitors | Peak NanoPlex™ Capacitors |

|---|---|---|

| Energy Density | Low density → oversized, heavy banks | HDC stores 4x more energy in the same footprint |

| Heat Tolerance | Derates above 85°C → requires oversizing or cooling | LDF runs reliably at 135°C with no derating |

| Ripple & Load Swings | Break down under high ripple, fast switching, inverter loads | Stable under ripple, harmonics, and fast switching |

| Power Quality | Poor voltage control, drift, and power factor issues | Maintains stable voltage & near-unity power factor |

| Service Life | Short lifespan → frequent field swaps & downtime | LDF lasts up to 5x longer under thermal & electrical stress |

| Cooling & Fuel | Runs hot, forcing larger radiators & generators | Lower dissipation cuts self-heating, cooling, and fuel needs |

| Deployment Fit | Bulky designs struggle in mobile or space-limited units | LDF's drop-in replacement offers no retooling and no redesign |

| Maintenance | Frequent replacements drive higher logistics costs | Fewer replacements, lower maintenance costs, longer uptime |

| Supply Chain | Heavily import-dependent, vulnerable to delays & geopolitics | 100% U.S. engineered, allied-sourced materials, secure supply |

Ready to Evaluate NanoPlex films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

Frequently Asked Questions

Traditional capacitors are heavy, oversized, and lose performance in the heat. NanoPlex HDC films deliver 4x more energy in the same footprint, enabling smaller, lighter mobile power units that deploy faster and run more reliably in the field.

Yes. Most traditional films fail above 85°C, forcing engineers to oversize or add cooling. NanoPlex LDF films run at full strength up to 135°C with no derating, making them ideal for sealed enclosures, hot climates, and compact mobile systems.

Mobile power units face constant thermal and electrical stress that quickly degrades standard films. NanoPlex LDF films last up to 5x longer, reducing field replacements, cutting maintenance cycles, and maximizing uptime during critical missions.

Traditional capacitors often break down under ripple and harmonics, causing unstable voltage. NanoPlex films maintain steady voltage and near-unity power factor, even under heavy switching, protecting sensitive equipment in mobile substations.

More than 70% of traditional capacitor films are imported, exposing operators to delays and cost swings. NanoPlex capacitor films are 100% U.S.-engineered and manufactured with allied-sourced materials, providing reliable delivery and supply security for utilities, defense, and OEMs.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.