Hybrid Power Factor Correction

Peak NanoPlex™ capacitor films maintain stable voltage and deliver reliable high-current performance, enabling hybrid power factor correction for grid modernization.

Purpose-Built for Hybrid Power Factor Correction

EV charging, AI data centers, and renewable energy surges put today’s grid under extreme stress, and traditional capacitors can’t keep up with the heat, fast load changes, or long duty cycles.

- NanoPlex HDC capacitor films provide 4x more energy storage in the same footprint.

- NanoPlex LDF capacitor films deliver reliable high-current performance, last up to 5x longer, and provide a drop-in upgrade that reduces maintenance and downtime.

Keep Power Steady Through Surges and Dips

- Solar and wind don’t deliver steady output; they surge and dip. These rapid swings can cause voltage spikes, sags, and poor power factor. Traditional capacitors can’t react fast enough, creating imbalances, outages, and instability across the grid.

- NanoPlex films for capacitors respond up to 4x faster than traditional designs, instantly absorbing or releasing reactive power to smooth fluctuations in real time. Built for hybrid power factor correction, they keep grids balanced under even the sharpest renewable output swings.

- Operators maintain stable voltage and near-unity power factor, reducing disruptions and protecting equipment. The result is a more resilient, efficient grid that can confidently integrate renewables while keeping service reliable for customers.

Stable Power Under Heavy Demand

- Industrial equipment, EV fast chargers, and AI data centers create sudden spikes in power demand. These sharp load shifts disrupt voltage alignment, weaken power factor, and put grid reliability at risk. Traditional capacitors can’t react quickly enough, leaving operators exposed to instability.

- NanoPlex capacitor films feature ultra-low impedance and deliver rapid bursts of reactive power for hybrid power factor correction. They respond faster during load spikes, keeping voltage and current in sync when it matters most.

- Utilities and operators maintain a stronger power factor, smoother voltage, and a more stable grid in environments with unpredictable, high-frequency load changes. The result: fewer disruptions, better efficiency, and greater confidence in grid performance.

Keep Harmonics in Check While Improving Reliability

- Renewables, storage, and inverter-based systems often introduce unwanted harmonics—electrical noise that disrupts power quality, overheats equipment, and threatens grid stability. Traditional capacitors struggle to filter these distortions, leaving sensitive devices exposed to risk.

- NanoPlex capacitor films are designed for hybrid power factor correction with ultra-fast, low-impedance performance. They suppress distortion across a wide frequency range, keeping total harmonic distortion (THD) below 3% for consistently cleaner power.

- Operators deliver high-quality power with less equipment heating, lower noise, and stronger protection for everything from grid-tied inverters to critical downstream electronics. The result: improved reliability, reduced maintenance, and a grid ready for modern renewable integration.

Built to Endure Constant Switching Stress

- Hybrid power factor correction systems expose capacitors to high ripple current, rapid cycling, and constant heat. Traditional capacitors break down quickly under these stresses, leading to premature failure, costly oversizing, and added cooling requirements.

- NanoPlex LDF capacitor films are engineered for high-demanding conditions and operate continuously. They hold full capacitance and dimensional stability even under sustained ripple and thermal fatigue.

- Operators gain long-term reliability without oversizing or active cooling. Resulting in fewer failures, reduced downtime, and lower maintenance costs, keeping hybrid PFC systems efficient and dependable at high frequency.

More Uptime, Less Maintenance

- Traditional capacitors wear out quickly under heat and heavy cycling. In hybrid power factor correction systems, this results in frequent replacements, higher maintenance costs, and unplanned outages that compromise reliability.

- NanoPlex HDC capacitor films are built for endurance, lasting up to 5x longer with nanolayered construction, thermal resilience, and self-healing properties. They maintain stable performance in demanding environments where traditional films fail.

- Operators reduce replacements, cut maintenance costs, and maximize uptime. Whether in remote substations, underground networks, or mobile units, NanoPlex delivers long-lasting reliability and a lower total cost of ownership.

Peak Expands Capability Without Expanding Space

- Traditional capacitors have already maxed out their performance in today’s compact substations, hybrid power factor correction banks, and urban grid sites. With limited energy density, they leave no room to add the functionality modern grids demand.

- NanoPlex HDC capacitor films deliver up to 4x more energy in the same footprint, unlocking higher performance, greater resilience, and longer service life without redesign or added space.

- Utilities and OEMs can build advanced hybrid systems that fit within existing layouts, gaining more power, stability, and reliability from the same enclosure. The result: modern capability without the cost or complexity of expanding system size.

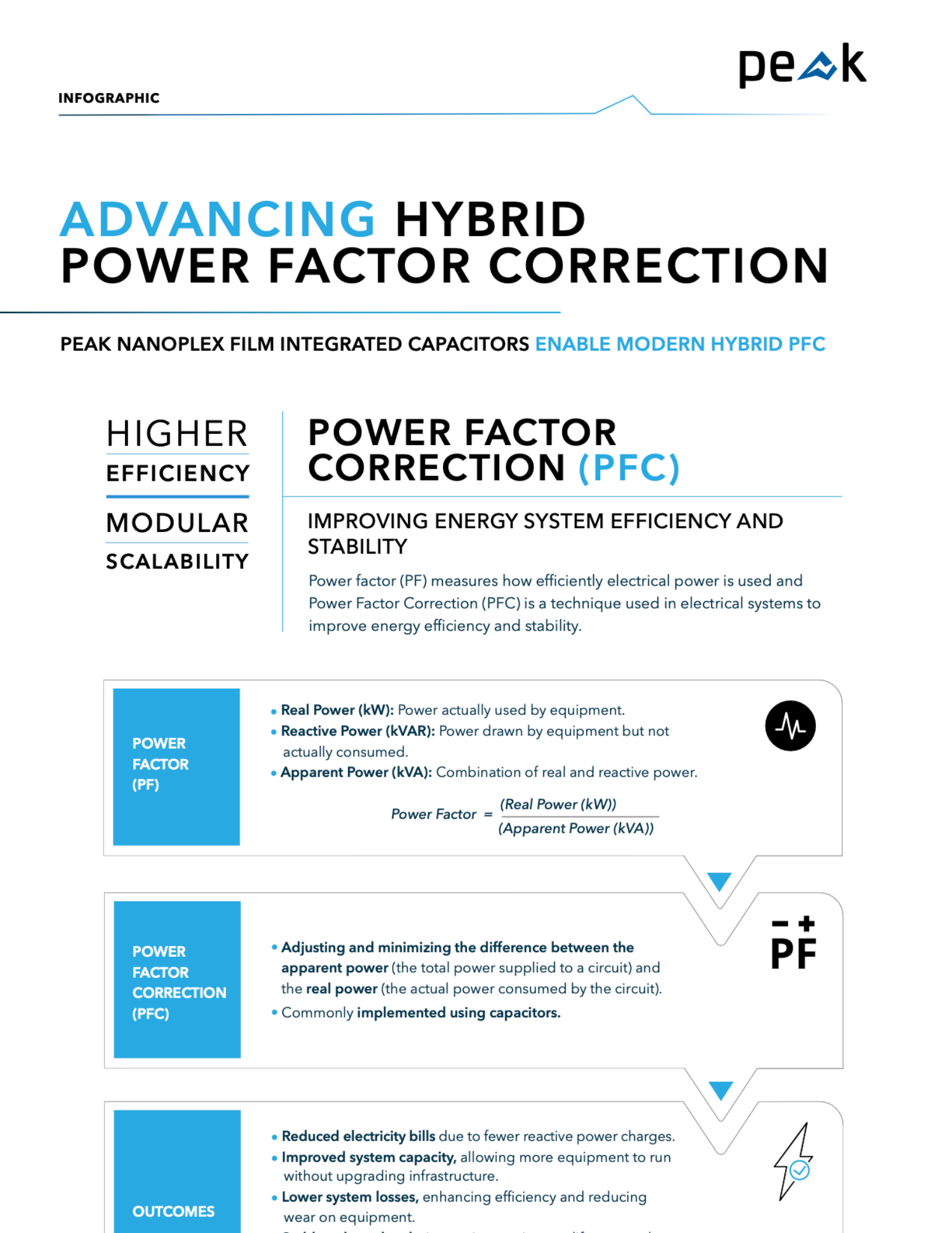

Traditional Capacitors vs. Peak NanoPlex™ Capacitor Films

NanoPlex capacitors provide utilities, OEMs, and operators with smaller, cooler, longer-lasting hybrid power factor correction banks that are securely U.S.-engineered and manufactured, and ready for modern renewable, EV, and high-frequency grid demands.

| Category | Traditional Capacitors | Peak NanoPlex Capacitors |

|---|---|---|

| Heat Tolerance | Begin to degrade around 85°C, requiring oversizing or active cooling | LDF runs reliably at 135°C with no derating, eliminating oversizing and cooling costs |

| Service Life | Short lifespan under heat and ripple stress → frequent replacements, outages, and higher maintenance | HDC lasts up to 5x longer life under cycling and thermal stress, cutting failures and downtime |

| Energy Density | Low energy density → oversized, heavy capacitor banks that strain space-limited sites | HDC stores 4x more energy per unit volume → banks up to 50% smaller and 30% lighter |

| Grid Stability | Struggle with voltage swings, ripple, and phase shifts from renewables and storage | Fast, stable response to load changes, maintaining near-unity power factor, and reliable voltage |

| Power Quality | Limited filtering → higher distortion, more noise, risk to sensitive equipment | Suppresses harmonics, keeping THD below 3%, protecting inverters and electronics |

| Efficiency | Higher dissipation factor → more self-heating and wasted energy | Lower dissipation factor → cooler operation, less loss, and improved efficiency |

| Scalability | Oversized banks limit use in mobile substations, modular units, or dense urban installs | HDC offers a compact design that supports mobile, modular, and space-constrained hybrid PFC systems |

| Deployment | Require retooling or redesign to upgrade | LDF's drop-in replacement offers no retooling and no redesign |

Ready to Evaluate NanoPlex films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

Frequently Asked Questions

Traditional capacitors can’t respond quickly to the surges and dips from solar, wind, or variable generation. NanoPlex capacitor films keep voltage steady and power factor near unity during renewable fluctuations.

Most capacitors derate or fail above 85°C. NanoPlex LDF run at full performance up to 135°C with no derating, enduring ripple, cycling, and thermal stress without oversized banks or costly cooling systems.

NanoPlex capacitor films deliver ultra-fast bursts of reactive power with faster response to load imbalances, stabilizing voltage, and reducing downtime risks from high-frequency surges.

Inverter-based renewables and storage introduce harmonics that overheat and damage equipment. NanoPlex capacitor films suppress distortion and keep THD under 3%, protecting inverters, transformers, and downstream electronics.

More than 70% of traditional capacitor films are imported, adding cost and risk. NanoPlex LDF capacitor films are engineered and manufactured in the U.S. with allied-sourced materials, lasting up to 5x longer and ensuring a stable supply with faster delivery.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.