AI Datacenters

Peak NanoPlex™ capacitor films give AI data centers stable, efficient, and reliable power; running cooler, lasting longer, and fitting into smaller footprints, so operators can cut downtime, reduce costs, and scale workloads faster.

NanoPlex™ Capacitors: High-Temperature, High-Frequency Power for AI Infrastructure

Peak NanoPlex films are engineered for the extreme power demands of AI data centers. Unlike traditional capacitors, they sustain performance under heat, ripple, and high-frequency loads to keep AI infrastructure reliable and efficient.

- NanoPlex LDF capacitor films operate at full capacitance at 135°C with no derating.

- NanoPlex HDC capacitor films deliver 4x higher energy density in the same footprint, 5x longer service life under thermal and electrical stress, and a low-loss design that reduces ripple and harmonics for consistent voltage.

Power Capacitors That Scale with AI

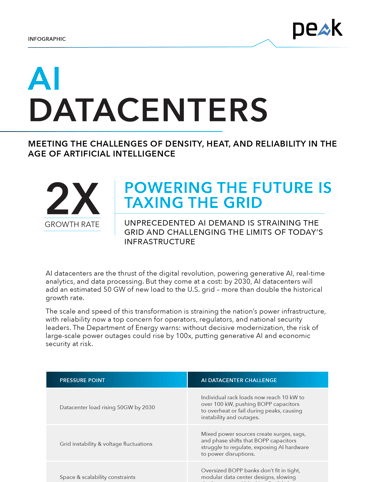

- AI workloads create unprecedented spikes in power demand, with unpredictable surges that traditional capacitors cannot absorb. These fluctuations stress capacitor banks, causing instability, overheating, and risking costly outages both on the grid and within the data center itself.

- NanoPlex HDC films deliver hybrid power factor correction with up to 4x the energy density of traditional designs. Their low-loss, high-frequency response allows them to absorb and release massive, variable loads without drift, derating, or performance loss.

- Utility and data center operators can scale AI infrastructure with stable, always-on power, eliminating oversizing and reducing thermal stress. The result is reliable uptime, efficient grid interaction, and the ability to expand AI Processing capacity without compromising resilience or efficiency.

Stable Power for AI

- AI data centers increasingly rely on a mix of grid supply, renewables, and on-site generation. These inputs create voltage fluctuations and phase mismatches that traditional capacitors cannot correct, threatening uptime and putting sensitive AI servers and accelerators at risk.

- NanoPlex capacitor films provide precise voltage stabilization and phase correction, engineered to respond instantly in complex hybrid energy environments. Unlike traditional designs, they maintain stable performance even under rapid switching, load spikes, and variable inputs.

- Utility power grid operators can provide consistent, reliable power delivery that protects mission-critical AI hardware from surges, sags, and disruptions. The result is stronger uptime, longer equipment life, and the ability to integrate diverse energy sources without compromising performance or reliability.

Energy Performance Without Limits

- AI data centers need high-density, modular power systems to keep pace with explosive workload growth. Traditional capacitors have reached their performance limits, requiring more units to deliver the same functionality. This limits scalability and makes it harder to deploy compact, modular facilities at the speed operators demand.

- NanoPlex HDC films deliver 4x the energy density in the same footprint, enabling compact, modular capacitor banks that integrate seamlessly with advanced power technologies like solid-state transformers (SSTs). This design unlocks scalability without sacrificing reliability or performance.

- Utility operators can accelerate deployment, maximize capacity in space-constrained environments, and future-proof AI data center infrastructure as workloads expand. The result is a flexible, efficient, and resilient power architecture that supports growth on both the grid and within the data center itself.

Stable Power Under Extreme Heat Generated by Workloads

- AI data centers are running hotter as workloads intensify and power density climbs. Traditional capacitors derate above 85°C, forcing operators to oversize banks, increase cooling capacity, or risk shutdowns that threaten uptime and efficiency.

- NanoPlex LDF films operate continuously at 135°C with no derating or capacitance drift. Their design maintains stable voltage and consistent performance in high-heat, power-dense environments where traditional films fail.

- Power grid operators can sustain safe, stable power under extreme heat while reducing cooling costs and eliminating the need to oversize capacitor banks. The result is improved reliability, lower operating expenses, and scalable infrastructure ready for AI-driven growth.

Peak Powers Real-Time AI with Reliable Cycling

- AI workloads push power systems harder than ever, demanding capacitors that can handle rapid charge and discharge cycles and frequent high-frequency switching. Traditional capacitors degrade quickly under these conditions, increasing the risk of downtime, costly replacements, and service interruptions.

- NanoPlex LDF films are engineered for fast, frequent cycling, maintaining stable performance through demanding power events. They deliver up to 5x longer service life and sustain 5x higher duty cycles than traditional capacitor designs.

- Power grid and datacenter operators can rely on continuous, around-the-clock power for AI servers and infrastructure. The result is fewer maintenance interruptions, lower replacement costs, and stable uptime to keep mission-critical AI workloads running without disruption.

Stable Access, No Delays

- AI data centers depend on a steady flow of reliable components, but global supply chain disruptions and reliance on offshore sources for traditional capacitor films create risk. Shortages, delays, and price volatility can jeopardize projects and increase operating costs.

- NanoPlex capacitor films are engineered and manufactured in the U.S., using allied-sourced materials and backed by more than 20 patents. This domestic foundation ensures uninterrupted supply, rapid delivery, and a secure alternative to offshore dependency. With a drop-in design, operators can upgrade without retooling or production delays.

- Operators gain a stable, North American supply chain that reduces risk, shortens lead times, and future-proofs AI data center investments. The result is greater confidence in project schedules, lower long-term costs, and supply resilience aligned with national security and energy independence goals.

Traditional Capacitors vs. Peak NanoPlex™ in AI Data Centers

NanoPlex capacitor films give AI data centers stable, scalable, and efficient power, handling massive spikes, high temperatures, and 24/7 duty cycles that traditional capacitors cannot.

| Category | Traditional Capacitors | Peak NanoPlex Capacitors |

|---|---|---|

| Operating Temperature | Derate above 85°C → require oversizing or costly active cooling | LDF runs reliably at 135°C with no derating, even in dense, high-heat server rooms |

| Energy Density | Limited capacity → more capacitors needed to support rack loads | HDC stores 4x higher energy density → supports 10–100 kW racks with fewer, smaller units |

| Cycling Performance | Degrade quickly under high-frequency charge/discharge cycles | LDF is optimized for fast, frequent cycling → stable under AI workloads with up to 5x duty life |

| Power Quality | Struggle with harmonics, ripple, and mixed input fluctuations | Low ESR design reduces ripple by 40% and keeps THD < 3%, protecting AI hardware |

| Service Life | Short lifespan in always-on, high-heat environments → frequent replacements | LDF lasts up to 5x longer under thermal and electrical stress → less downtime, lower O&M |

| Scalability | Oversized banks block modular layouts and slow deployment | HDC enables capacitor designs that are smaller and lighter, ideal for modular, high-density data center architectures |

| Deployment | Require redesign or retooling to upgrade | LDF's drop-in replacement offers no retooling and no redesign |

| Supply Chain | Over 70% imported film → exposed to global disruptions and long lead times | 100% U.S.-engineered and manufactured with allied-sourced materials → secure, resilient supply |

Ready to Evaluate NanoPlex films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

Frequently Asked Questions

AI inverters with SiC/GaN switch at high speeds, creating rapid charge/discharge cycles. Traditional capacitors degrade quickly, but NanoPlex LDF capacitor films are engineered for fast, frequent cycling lasting up to 5x longer under 24/7 AI loads.

Most BOPP capacitors derate above 85°C, forcing operators to oversize banks or add expensive cooling. NanoPlex LDF films run at full strength up to 135°C with no derating, cutting cooling costs and eliminating downtime.

Standard capacitors often fail under constant stress, leading to frequent replacements. NanoPlex LDF delivers up to 5x the service life, keeping mission-critical AI servers online longer and reducing total maintenance costs.

Spikes and ripple currents from AI workloads cause instability and risk outages. NanoPlex capacitors stabilize voltage, reduce harmonics, and provide consistent power delivery even during sudden load surges.

Over 70% of capacitor films come from offshore sources, creating risk. NanoPlex is U.S.-engineered, manufactured with allied materials, and designed to secure domestic supply for AI growth.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.