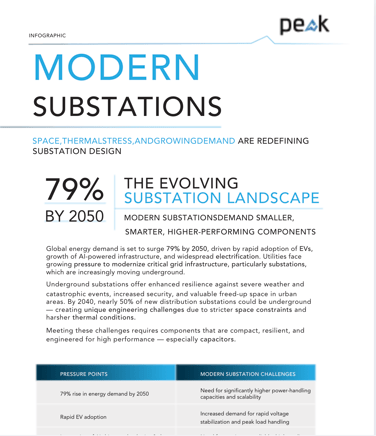

Substations

Engineered for substations, Peak NanoPlex™ capacitor films deliver smaller capacitor banks, fewer heat-related failures, and more stable power for AI and renewable-driven load growth.

Reliable Performance Where Substations Need It Most

Substations face rising heat, ripple, and harmonics that cause traditional capacitors to fail early, drift in voltage, and drive up maintenance costs.

- NanoPlex HDC capacitor films provide 4x energy density in the same footprint.

- NanoPlex LDF capacitor films operate at 135°C with no derating and last up to 5x longer under thermal and electrical stress, reducing ripple and harmonics to protect transformers and sensitive equipment.

Thermal Performance That Doesn’t Derate Under Pressure

- Substations are isolated, operate in dense areas, are sealed, and run hotter, pushing traditional capacitors past their limits. High heat and fast switching cause drift, derating, and frequent failures that raise maintenance costs and threaten reliability.

- NanoPlex LDF films deliver full-rated capacitance up to 135°C with no derating, shrinkage, or performance loss. With self-healing properties, they resist micro-faults and ensure long-term stability in the harshest substation environments.

- With NanoPlex capacitor films, utilities can build smaller, cooler, and more reliable capacitor banks without active cooling. The result is greater reliability, lower operating costs, and substations ready to handle rising demand and thermal pressure.

Scale Performance Where Space is Limited

- Distribution substation and underground substations operate in dense areas. Traditional capacitors can’t scale performance in these environments, requiring more units to meet demand, which drives up cost, complexity, and installation time.

- NanoPlex HDC films scale where traditional designs stop, delivering up to 4x more energy density in the same footprint. This enables higher performance without adding size, weight, or extra components.

- Engineers can gain more power and advanced filtering in the same space, streamlining installation and cutting infrastructure costs. The result is a reliable, high-density solution that keeps substations efficient under space constraints.

Stabilize Voltage and Protect the Grid

- Substations face rising harmonic distortion from inverter-based renewables, storage systems, and industrial loads. These harmonics create electrical noise that overheats equipment, degrades power quality, and threatens the reliability of sensitive downstream electronics. Traditional capacitors struggle to filter these high-frequency distortions.

- NanoPlex capacitor films are engineered with ultra-low impedance and high-frequency response, allowing them to suppress harmonics across a wide spectrum. By keeping total harmonic distortion (THD) below 5%, they stabilize voltage, reduce noise, and improve power factor in hybrid power correction systems.

- Utilities and OEMs can deliver high electrical quality, cleaner, more reliable power from substations, protect critical infrastructure, and extend equipment life. With controlled harmonics, substations operate more efficiently, reduce maintenance costs, and maintain compliance with increasingly strict power quality standards.

Stable Power for Long-Distance Transmission

- Long HVDC cable runs and shifting loads introduce voltage ripple that traditional capacitors struggle to smooth out. This instability weakens grid performance, increases heating losses, and puts sensitive equipment at risk across renewable and cross-border networks.

- NanoPlex capacitor films feature ultra-low ESR (Equivalent Series Resistance), meaning they waste less energy in heat, run cooler, and respond faster to high-frequency switching. With rapid frequency response, they reduce voltage ripple, maintaining efficiency under heavy ripple and load swings.

- Utilities and operators can maintain tighter voltage control over long distances, protect critical equipment, and deliver higher power quality. The result is more reliable HVDC transmission, better integration of renewable energy, and reduced maintenance costs.

Withstanding the Elements Surrounding Substations

- NanoPlex LDF capacitor films are hermetically sealed and chemically resistant, preventing moisture ingress and corrosion. Their design ensures stable operation even in the harshest substation environments.

- Capacitor banks remain in service up to 5x longer with fewer failures, reducing maintenance cycles, minimizing downtime, and lowering replacement costs. Utilities gain more reliable, lower-maintenance substations that remain resilient in demanding deployments.

Secure Substations with a Stable Domestic Supply

- NanoPlex capacitor films are engineered and manufactured in the U.S., using materials sourced exclusively from allied nations. A domestic supply provides a secure and resilient supply chain.

- Over 70% of capacitor film is imported, leaving utilities and OEMs exposed to geopolitical risk, long lead times, and unpredictable costs. Traditional capacitors built on these imports create uncertainty for critical substation projects.

- Manufacturers and utilities can have confidence in a reliable, North American supply of capacitor film that meets Buy American standards, cuts delivery risk, and supports cost control for long-term grid modernization.

Traditional Capacitors vs. Peak NanoPlex™ Capacitors

NanoPlex capacitors improve power quality, reduce costs, and ensure reliable performance in the high-heat, high-frequency, space-constrained environments of modern substations.

| Category | Traditional Capacitors | Peak NanoPlex Capacitors |

|---|---|---|

| Operating Temperature | Derate above 85°C, requiring oversizing or active cooling | LDF runs reliably at 135°C with no derating, even in sealed or underground substations |

| Energy Density | Low density; more units needed to meet demand | HDC stores 4x higher energy density, enabling 50% smaller and 30% lighter capacitor banks |

| Service Life | Short lifespan under heat, ripple, and cycling → frequent replacements | LDF lasts up to 5x longer, reducing failures, downtime, and O&M costs |

| Power Quality | Struggle with ripple and harmonics; voltage drift under fast switching | Ultra-low ESR design cuts ripple by 40%, lowers THD below 3%, and stabilizes voltage |

| Efficiency | Higher dissipation factor → more self-heating, wasted energy | Lower dissipation factor, runs cooler, reduces losses, and improves efficiency |

| Scalability | Bulky designs can’t scale performance in tight substations | HDC delivers more power in the same footprint, enabling compact, high-capacity capacitor banks |

| Environmental Durability | Vulnerable to moisture, salt, and pollutants → corrosion and early failures | Hermetically sealed and chemically resistant, ensuring reliable operation in harsh sites |

| Deployment | Require retooling or redesign to upgrade | LDF's drop-in replacement offers no retooling and no redesign |

| Supply Chain | Over 70% of film imported → exposed to geopolitical risk, long lead times | 100% U.S.-engineered and manufactured with allied-sourced materials for secure supply |

Ready to Evaluate NanoPlex films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

Frequently Asked Questions

Traditional capacitors degrade quickly in enclosed, high-heat, or moisture-prone environments. NanoPlex LDF films are hermetically sealed, chemically resistant, and run at full performance up to 135°C with no derating, ideal for sealed or underground substations.

Bulky capacitor banks take up space and limit capacity expansion. NanoPlex HDC capacitor films deliver 4x the energy density of traditional films, allowing utilities to cut bank size by up to 50% while increasing performance in the same footprint.

Most capacitors fail every 2–3 years under high heat, ripple, and harmonics. NanoPlex LDF films last up to 5x longer, even in extreme environments, reducing maintenance cycles, downtime, and replacement costs.

Inverter-heavy grids introduce harmonics and ripple that traditional capacitors struggle to filter. NanoPlex capacitor films use ultra-low ESR design to cut ripple by 40% and keep THD (total harmonic distortion) below 3%, delivering cleaner, more stable power for sensitive equipment.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.