Peak NanoPlex™ High Dielectric Constant Film (HDC)

Ultra Energy-Dense Film for Next-Generation Capacitors

Request a Sample KitHigh-Energy, High-Stability Film Technology Engineered for Demanding Power Systems

NanoPlex HDC films are advanced nanolayered dielectric materials that significantly increase the energy storage capacity of capacitor films. Built with Peak’s patented metamaterials and U.S.-based manufacturing, HDC films deliver higher energy density, improved thermal stability, and longer device lifetimes in compact footprints.

HDC films are specifically formulated to deliver high energy density in demanding pulse power applications. Best performance is obtained in oil-impregnated film/foil capacitor formats that yield high shot life coupled with significant reduction in device size and footprint.

The Next Generation of High-Density Dielectric Films

Up to 4x More Energy Storage

NanoPlex films enable smaller and lighter capacitors, which reduces space and infrastructure requirements while helping to cut overall capacitor costs.

2x Smaller Capacitor Footprint

NanoPlex HDC enables capacitor designs that are 2x smaller, reducing the footprint and overall cost.

Higher Thermal Stability (Up to 105°C)

NanoPlex’s higher temperature capabilities enable functionality in hotter environments while reducing cooling demands on the system and thus reducing overall system weight and cost.

Higher Shot Life

Enable >2x times more pulse discharges than pulse power capacitors built to the same capacitance and voltage ratings using other commercial polymer films.

U.S.-Engineered, Lab-Tested

Backed by 20+ Global Patents, ASTM and JIS-certified performance data.What Is Peak NanoPlex™ HDC?

NanoPlex™ HDC Film vs. Conventional Capacitor Films

| Feature / Property | Conventional Capacitor Film (BOPP / PET) | NanoPlex HDC Film |

|---|---|---|

| Dielectric Constant (εᵣ) | ~2.2 (BOPP), ~3.3 (PET) | 3.8 – 4.9 |

| Energy Density | Baseline | Up to 4x higher energy storage per unit volume |

| Thermal Operating Limit | 85°C typical (BOPP), 105°C with de-rating (PET) | Up to 105°C without de-rating |

| Footprint / Size Efficiency | Requires more volume to match HDC capacity | Up to 2x smaller capacitor banks |

| Lifetime at High Temp | Shorter lifespan, early failure in hot environments | Longer lifespan due to reduced thermal stress |

| Material Composition | Single or few-layer polymers | Nanolayered metamaterial (up to 4,096 layers) |

| Manufacturing Location | Largely foreign-sourced (China, Europe, India) | 100% U.S.-based production |

| Supply Chain Security | Exposed to foreign dependency & tariff risk | Secure, ITAR-compliant, DoD-preferred |

| Applications | General purpose capacitors | Fusion, EMALS, EV, HVDC, Aerospace |

| Patent Protection | Commodity-grade, limited IP | 20+ Global Patents |

| Custom Thickness & Metallization | Often fixed grades only | Available on request |

Ideal for High-Energy Applications

Aircraft EMALS & Directed Energy Systems

Mobile Grid Solutions

Laser Fusion Reactors & Inertial Confinement Fusion

Motor Start Applications

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex HDC for in-house qualification, compatibility testing, and grid-level performance validation.

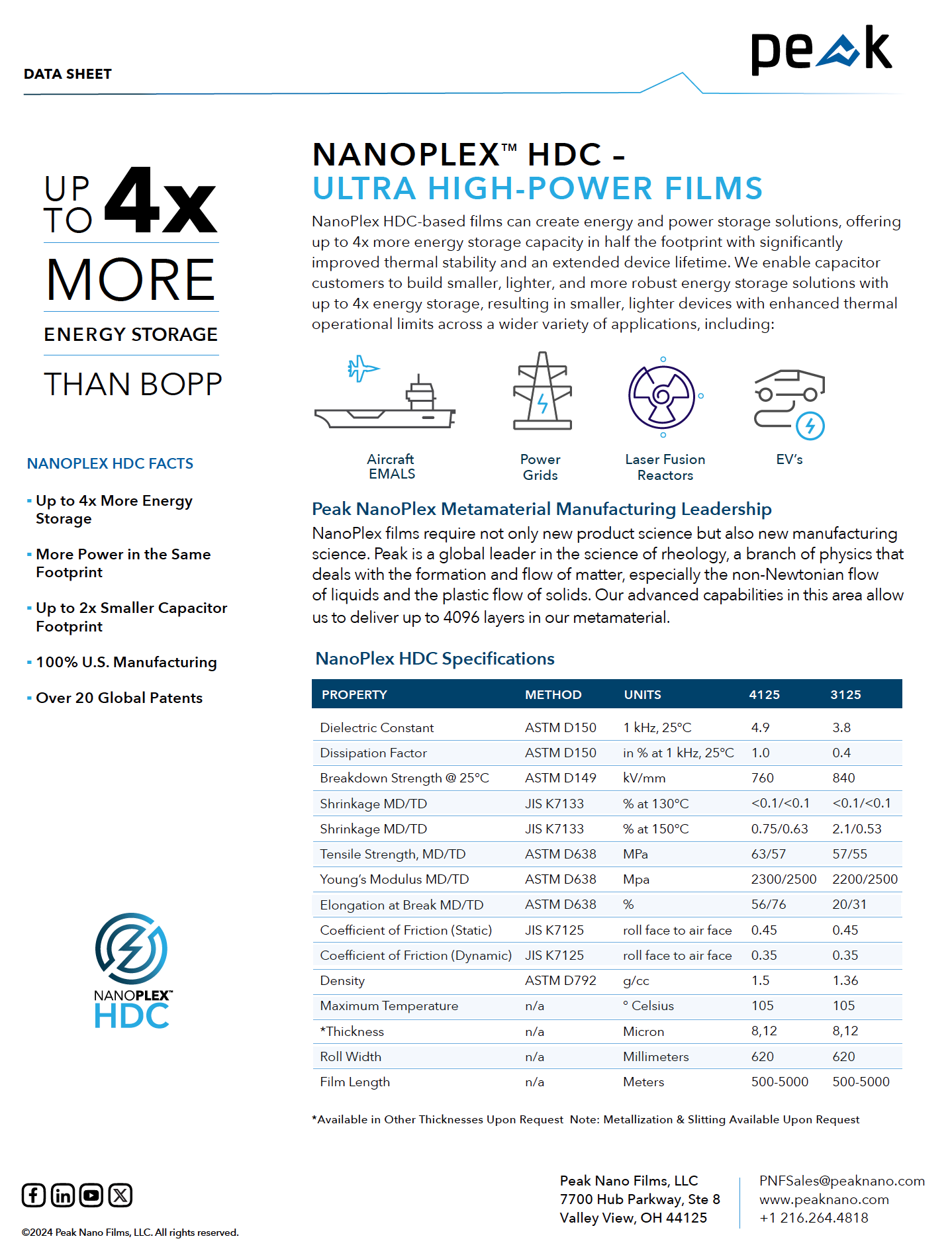

NanoPlex™ HDC Film Specifications

| Property | Method | Units | HDC (4125) | HDC (3125) |

|---|---|---|---|---|

| Dielectric Constant | ASTM D150 | 1 kHz, 25ºC | 4.9 | 3.8 |

| Dissipation Factor | ASTM D150 | in % at 1 kHz, 25ºC | 1.0 | 0.4 |

| Breakdown Strength @ 25°C | ASTM D149 | kV/mm | 780 | 840 |

| Shrinkage MD/TD | JIS K7133 | % at 130°C | <0.1/<0.1 | <0.1/<0.1 |

| Shrinkage MD/TD | JIS K7133 | % at 150°C | 0.75/0.63 | 2.1/0.53 |

| Tensile Strength, MD/TD | ASTM D638 | MPa | 63/57 | 57/55 |

| Young’s Modulus MD/TD | ASTM D638 |

Mpa |

2300/2500 | 2200/2500 |

| Elongation at Break MD/TD | ASTM D638 | % | 56/76 | 20/31 |

| Coefficient of Friction (Static) | JIS K7125 | roll face to air face | 0.45 | 0.45 |

| Coefficient of Friction (Dynamic) | JIS K7125 | roll face to air face | 0.35 | 0.35 |

| Density | ASTM D792 | g/cc | 1.5 | 1.36 |

| Maximum Temperature | n/a | ° Celsius | 125 | 125 |

| *Thickness | n/a | Micron | 6,8,12 | 6,8,12 |

|

Roll Width |

n/a | Millimeters | 620, 740 | 620, 740 |

| Film Length | n/a | Meters | 500-5000 | 500-5000 |

*Metallization, slitting, and other thicknesses available upon request.

Frequently Asked Questions

NanoPlex HDC is a nanolayered, high dielectric constant capacitor film developed by Peak Nano. It offers up to 4x greater energy storage in the same footprint, withstands higher temperatures (up to 105°C without de-rating), and enables smaller, lighter capacitor designs. Compared to BOPP or PET, HDC delivers superior thermal, electrical, and mechanical performance - especially in demanding environments like fusion energy systems and aerospace power platforms.

The dielectric constant (εᵣ) of NanoPlex HDC ranges from 3.8 to 4.9, compared to ~2.2 for BOPP. A higher dielectric constant directly correlates to greater energy storage capacity per unit volume, meaning capacitors can be made smaller while storing the same, or more, energy. This is critical in space-constrained or thermally demanding applications.

HDC film is ideal for pulsed power, high-voltage DC (HVDC) transmission, laser fusion reactors, military-grade EMALS, motor start solutions, and advanced aerospace power platforms. It excels in environments where thermal endurance, miniaturization, and reliability under stress are top priorities.

Yes. Peak Nano is currently scaling high-volume production for commercial availability. Customer samples are available, and custom configurations (e.g., metallization, slitting, thickness) can be discussed to match application-specific capacitor requirements.

NanoPlex HDC is 100% manufactured in the United States using patented nanolayered metamaterial technology. This ensures supply chain security, compliance with U.S. defense and energy regulations, and faster delivery cycles. Unlike foreign-sourced BOPP/PET film, HDC provides ITAR-safe, tariff-resistant sourcing that supports national manufacturing resilience.

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.