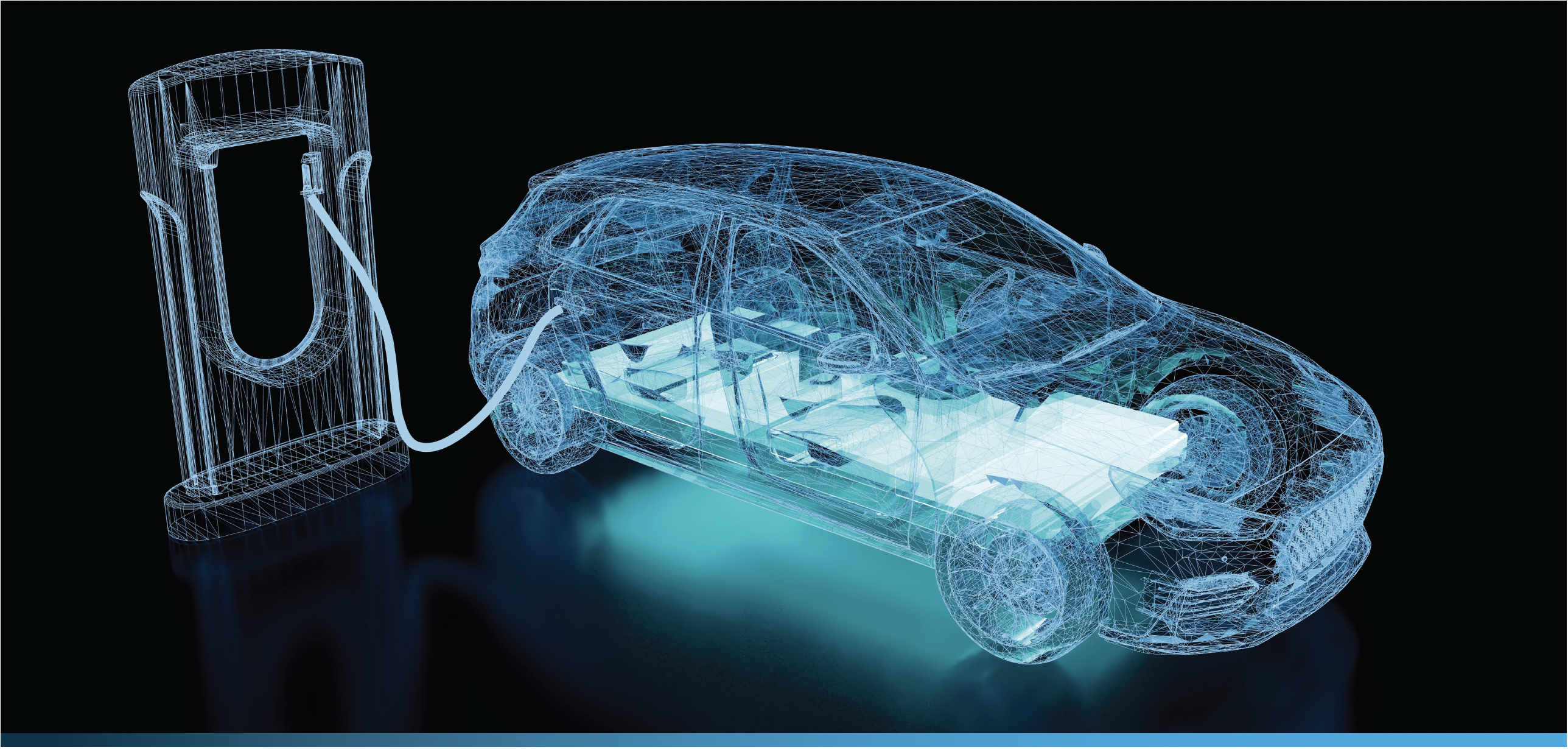

EV Drivetrain

Designed for EV drivetrains, Peak NanoPlex capacitor films handle higher ripple currents without derating, reducing energy loss, thermal load, cooling, and total system cost.

Peak NanoPlex™ capacitor films perform at full voltage even under high ripple conditions, extending lifetime and reducing cooling needs in EV power systems.

Peak NanoPlex Film capacitors support high-efficiency 900V drivetrains with superior thermal performance, lower cooling requirements, and longer operational life, requiring fewer parts per system.

- 135°C full capacitance, operates at full energy with no derating

- Lower Dissipation Factor in high temperature environments lowers self-heating for reduced cooling hardware needs

- Up to 5x longer service life, reliably endures high-temperature, high-ripple duty, cutting maintenance cycles

- Smaller capacitor banks shrink size and weight, delivering lighter EV systems at lower cost

- Up to 60% lower installed BOM, simplified designs, and reduced material costs

LDF capacitor films reduce weight, cut BOM costs, and support continuous high-ripple operation in 900V architectures without trade-offs.

- Engineered with nanostructured dielectric layers and a low dissipation factor, Peak NanoPlex LDF film capacitors thrive in ultra-high-frequency, high-voltage environments, supporting continuous operation at 135°C with no derating.

- Traditional BOPP-C capacitors break down under the high frequencies, ripple currents, and thermal loads of modern 900V SiC/GaN inverter systems, limiting drivetrain performance, lifespan, and reliability.

- LDF capacitors enable smaller, cooler, longer-lasting inverter systems, cutting BOM costs, reducing weight, and unlocking full power density for next-generation EV performance.

Engineered for high-ripple, high-frequency inverter banks, NanoPlex™ LDF capacitors reduce BOM size, thermal load, and failure risk.

- Engineered for sustained performance under extreme electrical and thermal stress. Peak NanoPlex LDF capacitors maintain full-rated voltage and capacitance at up to 135°C, requiring minimal derating, empowering engineers to maximize power density, minimize system size, and achieve long-term stability under continuous high-voltage loads.

- High-voltage inverters push traditional capacitor films past their limits. At elevated temperatures, BOPP-C films are prone to shrinkage, dielectric breakdown, and rapid aging, creating reliability risks for compact inverter banks and high-power EV drivetrains operating at 900V and beyond.

- Smaller, cooler, longer-lasting drive systems that deliver more miles per charge. By eliminating oversizing, reducing heat buildup, and extending service life, LDF capacitors cut total system cost, weight, and cooling demands, resulting in greater range, efficiency, and reliability for EVs and electrified machinery.

With no derating or over-engineering, LDF capacitor films provide full performance in less space, with fewer thermal shutdowns and lighter cooling.

- With thermal stability up to 135–145°C, LDF technology delivers consistent capacitance and eliminates the need for derating, in compact, high-power inverter environments. That means fewer thermal shutdowns, no shrinkage, and sustained performance in the most demanding electric vehicle designs.

- BOPP-C capacitors break down above 85°C, losing up to 30% of capacitance at 105°C, forcing engineers to oversize components and invest in bulky, expensive cooling systems. In high-voltage EV drivetrains, this heat-driven inefficiency compromises performance, range, and reliability.

- By reducing internal heat generation and cutting cooling system requirements, LDF film capacitors lower system weight and complexity, extend operational life, and enable smaller, more efficient power modules. The result: greater range, higher uptime, and better ROI for EV platforms pushing the limits of power density and endurance.

Extend system uptime and reduce failure risks with LDF capacitors that resist thermal fatigue and dielectric breakdown.

- Peak NanoPlex LDF capacitors deliver 3–5x longer service life than BOPP-C, even under harsh thermal and electrical loads. Their nanolayered construction resists dielectric fatigue, thermal stress, and capacitance loss over millions of charge-discharge cycles.

- In high-frequency, high-ripple environments, traditional BOPP-C capacitors degrade rapidly, leading to frequent replacements, increased maintenance, and system-level reliability concerns. For EV platforms operating around the clock, this wear-and-tear is costly and unsustainable.

- With dramatically extended lifetimes, LDF capacitors cut maintenance frequency, reduce downtime, and eliminate unplanned failures. For drivetrain engineers and fleet operators, that means lower lifecycle costs, higher reliability, and smoother vehicle performance.

BOPP-C vs. LDF in 900V Inverter Applications

| Feature | BOPP-C | NanoPlex LDF 1000 | NanoPlex LDF 2000 |

|---|---|---|---|

| Maximum Voltage Support | Up to 600V DC | Up to 1,000V DC |

Up to 1,400V DC |

| Lifetime at 105°C | ~2,000hr | 100,000hr |

100,000hr |

| Lifetime at 85°C | 200,000hr | 600,000hr |

600,000hr |

| Capacitance Loss at 105°C | -30% | <5% | <5% |

| Duty Cycle Support | Moderate | 3–5x higher than BOPP-C | 3–5x higher than BOPP-C |

| Cooling Required | High | Reduced | Significantly Reduced |

| Derating Requirement | Essential | Minimal | Minimal |

| Physical Shrinkage at 135°C | 3%+ | ~0% | ~0% |

| ESL/ESR at High Frequency | Higher | Lower | Lowest |

| Radiation Resistance | Standard | Improved | Highest |

| Supply Chain Security | Overseas Dependent | Domestic/Allied | Domestic/Allied |

| BOM Cost (Installed) | Higher—needs oversizing | Lower—no oversizing | Lowest—no oversizing/cooling |

Frequently Asked Questions (FAQs)

900V inverter systems deliver the same power with less current, reducing heat loss, cable weight, and charging time. This enables ultra-fast charging, greater energy efficiency, and improved performance for electric vehicles, forklifts, mining trucks, and other industrial equipment.

Capacitors in 900V systems must withstand higher dielectric stress, frequent current spikes, and elevated internal temperatures, often beyond what traditional BOPP-C capacitors can handle. This leads to shrinkage, early failures, and the need for oversizing or derating.

BOPP-C capacitors degrade rapidly above 85°C and lose up to 30% capacitance at 105°C. Their inability to tolerate high ripple currents and fast-switching environments makes them unreliable for next-gen SiC/GaN-based 900V inverters.

Peak LDF capacitors are engineered with a nanolayered structure and low dissipation factor, allowing them to operate reliably up to 135–145°C with minimal shrinkage, derating, or performance loss. They handle higher voltages and switching frequencies with superior stability and longevity.

Ready to evaluate NanoPlex films?

Request a sample kit for in-house qualification, compatibility testing, and grid-level performance validation.

Explore Our Electric Vehicle Resources

Ready to Evaluate NanoPlex Films?

Request a sample kit of NanoPlex for in-house qualification, compatibility testing, and grid-level performance validation.