Biodegradable Multilayer Polymer Films for Sustainable Packaging

Peak NanoPlex films receives Greater Akron Polymer Innovation Hub Award for its superior performance and barrier protection designed to advance sustainable end-of-life options for food and medical packaging.

A New Innovation Hub-Funded R&D Program

Peak Nano has been awarded R&D funding from the Greater Akron Polymer Innovation Hub to advance its work on biodegradable multilayer polymer films for food, beverage, and medical packaging applications. As one of the Hub’s first‑round funded projects, the initiative is part of a broader, state‑backed effort to accelerate industry‑driven polymer innovation, commercialization, and workforce growth in Northeast Ohio.

Selected through a competitive whitepaper process that reviewed more than 40 project proposals from companies and universities across the region, Peak Nano’s project is one of eight receiving Innovation Hub support, as the dedicated effort in “Biodegradable multilayer nanolayered polymer films for food and medical packaging”.

Why Multilayer Packaging Needs to Change

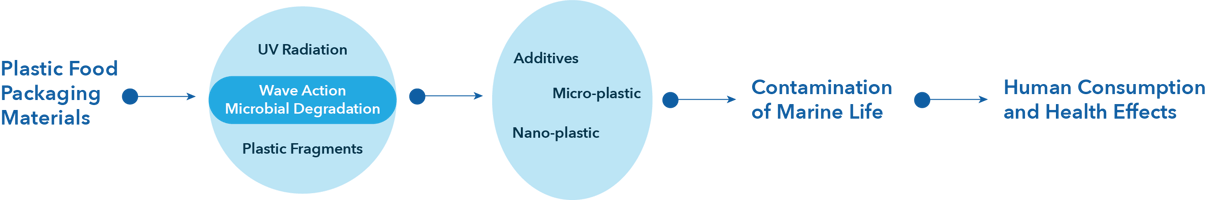

Conventional multilayer packaging films rely on many tightly bonded layers of polymers and additives that are extremely difficult to recycle using today’s systems. Over time, these structures fragment and shed micro‑ and nanoparticles into soils, waterways, and the broader environment, contributing to the growing problem of microplastics in the food chain.

Brand owners and film manufacturing companies are under pressure to maintain product safety and shelf life while improving the biodegradation profile of their packaging. Peak Nano’s goal is to deliver films that match or exceed current barrier and mechanical performance while being engineered for improved degradability and more responsible end‑of‑life pathways.

How NanoPlex™ Enables Biodegradable Multilayer Structures

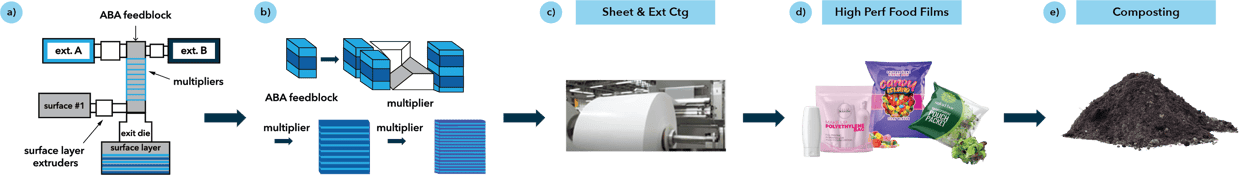

Peak Nano’s NanoPlex™ technology, developed at Case Western Reserve University, enables the creation of films containing thousands of precisely controlled polymer layers within a conventional coextrusion process. Unlike traditional melt‑blend approaches, NanoPlex™ uses nanoscale layering to combine multiple polymers so that multiple properties, from atmospherics to molecular permeability, biodegradability, conductivity, and insulation, can be integrated and fine-tuned.

For this Innovation Hub program, Peak Nano is:

-

Formulating films with biodegradable polymers such as poly(L‑lactide) (PLLA), polyhydroxyalkanoates (PHA), and poly(ε‑caprolactone) (PCL), combined with polyvinyl alcohol (PVOH), to build strong barrier systems.

-

Using nanoscale layer control to dial in barrier performance, mechanical strength, and degradability by adjusting individual layer thickness.

-

Applying nanolayer coextrusion and biaxial orientation to boost oxygen and water‑vapor resistance, improve durability, and reduce brittleness so films withstand real‑world converting and packaging operations.

Key technical advantages:

-

High oxygen and water‑vapor barrier performance.

-

Mechanical toughness and processability suitable for demanding food and medical applications.

-

Engineered degradability to help reduce long‑term microplastic accumulation in the environment.

Collaboration: Inside the Greater Akron Polymer Innovation Hub

Powered by the Polymer Industry Cluster and Greater Akron Chamber

Peak Nano’s biodegradable film program is being advanced in collaboration with researchers at Case Western Reserve University and The University of Akron, drawing on Northeast Ohio’s deep expertise in polymer science and advanced processing.

The work is part of the Greater Akron Polymer Innovation Hub, a $42 million effort (including $31.3 million from the State of Ohio and $10.4 million in partner matching funds to:

-

Build a polymer pilot facility with shared access to equipment for scaling new materials.

-

Fund industry‑driven innovation projects across mobility, healthcare, semiconductors, industrial materials, and energy, with sustainability as a common theme.

-

Support startups and established companies bringing sustainable polymer innovations to market.

The Innovation Hub is powered by the Polymer Industry Cluster (PIC), an industry‑driven consortium that now includes more than 50 members across the polymer value chain.

Program Phases: From Lab to Market

Peak Nano’s work is structured into stages that take NanoPlex™ films from concept to commercial‑ready solutions.

Lab Formulation & Prototype Films (Current Stage)

-

Develop lab‑scale film formulations using NanoPlex™ with PLLA, PHA, PCL, and PVOH.

-

Produce initial nanolayer film structures and verify processability on pilot‑scale equipment.

-

Collect early barrier and mechanical data and compare to performance data for incumbent non‑biodegradable multilayer structures.

Commercial Equipment Trials & Performance Benchmarking

-

Run prototype films on commercial converting and packaging equipment used in food and medical applications.

-

Benchmark oxygen and water‑vapor transmission rates and toughness against state‑of‑the‑art commercial food packaging.

-

Refine film architectures based on feedback from film converters and brand‑owner partners.

Biodegradability Testing & End‑of‑Life Assessment

-

Conduct biodegradability and environmental impact testing under relevant conditions (e.g., industrial composting or controlled degradation scenarios)

-

Compare fragmentation and microplastic generation profiles vs. conventional multilayer films.

Industry-Scale Manufacturing, Cost Modeling, and Commercialization

-

Develop industry-scale manufacturing and cost models for NanoPlex™ films, including production at Peak Nano’s Ohio facilities and/or partner converters.

-

Prepare product data sheets and technical documentation for food, beverage, and medical packaging customers.

-

Define commercialization pathways: direct film supply, partnerships with converters, and co‑development programs with brand owners.

Building Sustainable Materials and Creating STEM Jobs in Ohio

This biodegradable packaging initiative is part of Peak Nano’s broader commitment to creating advanced manufacturing capacity and STEM employment in Ohio. The company is investing in expanded facilities in Northeast Ohio and aligning its NanoPlex™ development with the state’s Sustainable Polymers Tech Hub designation and the Greater Akron Polymer Innovation Hub’s long‑term economic growth strategy.

By anchoring NanoPlex™ R&D, scale‑up, and production locally, Peak Nano is helping translate Ohio’s century‑long polymer heritage into next‑generation sustainable materials, new startup and supplier opportunities, and high‑value technical roles across the region.

For Brand Owners, Converters, and Researchers

Peak Nano is engaging:

- Brand owners exploring more sustainable barrier films for food, beverage, and medical applications.

- Converters and packaging manufacturers interested in running NanoPlex™ films on commercial lines.

- Researchers and innovation partners focused on sustainable polymers, biodegradability, and circular packaging.

Request a Technical Discussion

Connect with our materials team to discuss use cases, performance targets, and pilot opportunities.